Brainpower vs. horsepower: an alternative future for ag equipment

Elliott GrantFounder, CEO

Sometimes fresh eyes and a simple question are all it takes to change the status quo.

Many game-changing inventions have come from someone asking, “Why does it work like that?” MIT’s Brynjolfsson & McAfee described how the Polaroid camera, Airbnb, and Netflix were inspired by exactly that question in their book about the rapid changes enabled by technology: The Second Machine Age.

Image: generated by Gemini.

The agriculture industry should be asking those “why” questions, too. Should the way food production is done today be how it will always be done? Which assumptions about our resources, management practices or tooling should we revisit? At Mineral, we are applying breakthroughs in AI to agriculture. What we learn inspires us to challenge what exists today – asking how AI could precipitate transformational and disruptive change.

Why is farm equipment so big?

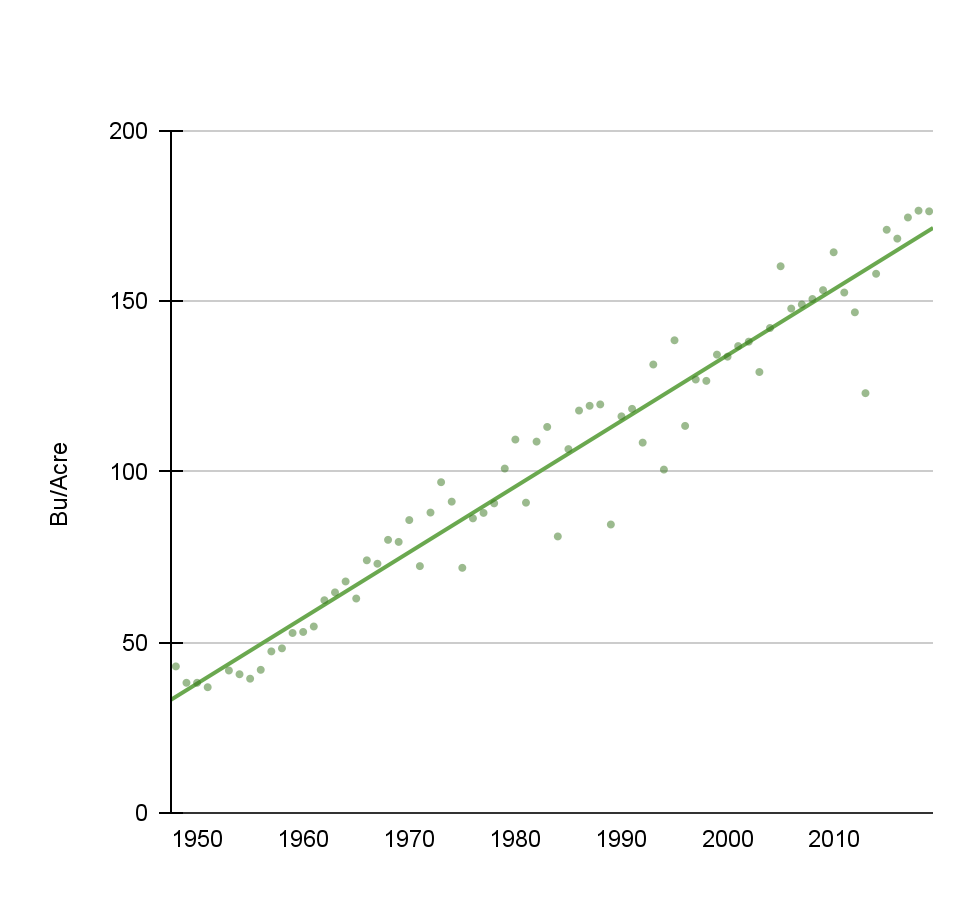

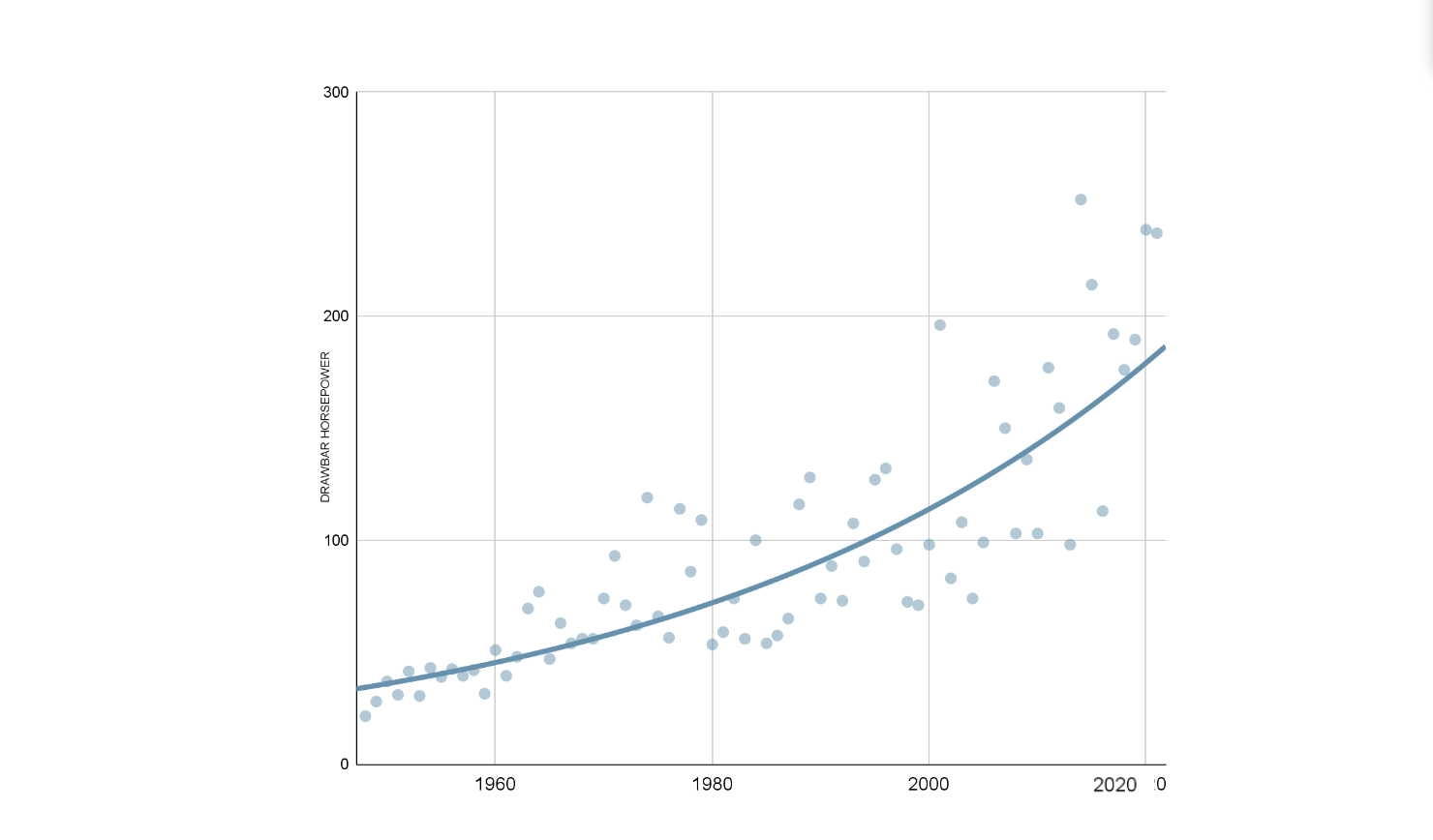

It might be one of production agriculture’s most common visual tropes – a mighty piece of farm machinery moving through a sea of crops, from dawn to dusk. And over the last 75 years, while U.S. crop yields increased 4x, tractor drawbar horsepower and the weight of a fully loaded combine both increased by nearly 10x. These trends reflect farm operators’ need to move bigger tools across more acres more efficiently - and with less labor. So machines grew bigger and more powerful. Indeed, John Deere recently announced its latest 9RX tractor is their, “biggest tractor yet,” with a maximum engine power of 830 horsepower.

Average corn and grain yield in the U.S. between 1950 and 2020.

Median tractor drawbar horsepower between 1950 and 2020.

While large farm equipment certainly improves input productivity, it also has consequences. Some are obvious, such as the high cost of a new self-propelled sprayer – which can go for more than $500,000 - that makes equipment less accessible to small farms, and drives consolidation. Greater mass can increase soil compaction that inhibits root growth and impairs water infiltration.

But the less visible impact of farm equipment’s bigness is risk. Big, expensive machines (and their labor) need to be amortized across a lot of acres. Consequently, this limits the time equipment can spend in each field, giving farmers only a few opportunities each season to take high-consequence actions - and allowing for even fewer opportunities to observe their crops.

This has become the sine qua non of farming: farmers make a few high-stakes decisions every year, such as seed selection, and the timing of weed control, nutrient, fungicide and insecticide applications.

Farmers have only a few opportunities each season to make high-consequence decisions and take action.

- Every season, every farmerEvery season, every farmer decides whether to apply herbicides, which active ingredients to use, when to apply them and how much. These full-farm decisions are informed by manual scouting.

- Picturing precision in real timeIn an ideal world, specific chemicals would be applied precisely, at the right times, in exactly the right quantities - saving the farmer money, minimizing contributions to resistance, and reducing the environmental impact of excess spraying.

- Risk to farmers remains highIn reality, today a farmer scouts a sample of their fields looking for evidence of problems that require action. They then decide to spray one tank mix and do it - usually - in a single pass. Under these constraints, a farmer’s only risk management tool against a bad decision (or bad luck) is crop insurance.

The good news is that precision technologies, enabled by AI, are starting to come to market that will detect plant species and only spray weeds - which is an important and welcome improvement. But this is a sustaining innovation of the current way of working - not a disruptive one (1). So what would a disruptive paradigm look like for agriculture?

More brain power, less horsepower

With advancements in AI happening at an exponential rate, we can imagine a near future in which farm machinery is smarter, fully autonomous and - counterintuitively - smaller. Full autonomy for farm equipment is already here. Perception systems are close to being able to identify individual plant species, plant growth stages, and plant health signals, and doing all of that ‘on the edge’. All-electric rovers are showing up - and will continue to improve in range and power, along with charging and tendering infrastructure. Multiple startups are developing and testing systems that could bring more accurate, autonomous actuation in common field tasks. Improved internet connectivity, such as via satellite, promises to close the rural connectivity gap. Together these technologies will enable a new era for farm operations: Continuous Management.

Instead of a few passes through a field at 10mph by large, heavy machinery, farming with lighter-weight, more nimble, autonomous devices would allow for continuous monitoring and action, day-in and day-out. Continuous Management would represent a paradigm shift in agriculture - not only because greater precision would reduce chemical usage and improve yields - but because it would radically change a farmer’s risk calculation. It trades horsepower for brainpower … of the AI type.

A fleet of AI-equipped rovers would reduce a farmer’s exposure to a single, expensive machine becoming unavailable. Perception, reasoning and action done by software-defined, low-cost machines stacks dozens of smaller, lower-risk decisions throughout a season, reducing a farmer's reliance on a few high-stakes decisions and crop insurance. These rovers inspect a whole field, not just scout a sample, and can catch problems earlier.

Continuous Management would represent a paradigm shift in agriculture, because it would radically change a farmer’s risk calculation. It trades horsepower for brainpower … of the AI type.”— Elliott Grant, CEO, Mineral

Sound radical? Consider the transformation in healthcare from infrequent interventions (e.g. blood tests) to continuous monitoring and care (e.g. continuous glucose monitors). Shifts to more precise, lower risk models are already happening.

We’re not the only ones willing to imagine a new paradigm for agriculture. Shane Thomas discussed this concept of continuous monitoring and management in his Upstream Ag blog about Solinftec’s Solix platform. As Shane mentions, while, “no companies are capable of doing [cost- and time-efficient sensing, diagnosis, action] today,” - Solix is an existence proof that challenges the current, “thinking that has been around layering on technology to the current paradigm.”

Disruptive innovations are often dismissed or ignored by mainstream customers (and therefore suppliers) because they are initially less capable than their existing solutions. Small, electric, autonomous rovers certainly can’t replace all the jobs done by powerful farm equipment today. But these devices will start in niches, and steadily improve until they redefine the status quo. The Mineral team has been listening to farmers' interest in the data and insights a shift to Continuous Management would bring, emphasizing the potential time and resource savings, assuming the economics could work for them.

Mineral's all-electric rovers -- designed as a prototype for in-field data capture that enables AI model training using machine learning operations (ML Ops).

Unlocked: New opportunities – and a new paradigm – for agriculture

At Mineral, we’ve been building electric rovers and testing them on various jobs with partners on multiple crops around the world (2), and we’ve trained AI to understand 120+ different plant traits. We’ve developed custom ML pipelines that are the key to handling the extreme diversity and dynamism of agriculture domains, and solve the challenges of continuous and efficient model retraining.

These experiences convince us that Continuous Management is technically feasible and will unlock new services and value for farmers, such as:

Productivity Gains: More precise, timely crop scouting and problem resolution will capture yield improvement that is out of reach with today’s approach, while optimizing inputs at each plant to reduce waste. That improves both the top and bottom line for farmers.

New paths to revenue: Smaller machines can give farmers the ability to manage a greater diversity of crops, and plant-level classification opens the door to more sophisticated and selective chemistry.

Farmer-led innovation: Lightweight, mechanically simple equipment that can be repurposed with a code update should be far easier to operate and maintain. It could spark an explosion in open-source, farmer-to-farmer creativity and collaboration.

Expanded, personalized insurance or loan access: For farmers using specific practices that can be verified with continuous, autonomous monitoring.

Over the next decade, AI will play a critical role in greater crop resilience, improved productivity and lower environmental impact. We’re taking the first steps towards a more sustainable agriculture system - a journey which begins with being willing to ask “why?”

( 1 ): For more information on the difference between sustaining vs. disruptive innovations, read The Innovator’s Dilemma

( 2 ): Check out this project with UMN on detecting wheat rust.